Essential Tips for a Safe and Successful Rigging Setup

It is vitally important to adhere to safe rigging practices and ensure that every setup is thoroughly planned and executed. As part of our focus on emphasizing rigging safety, PRG Gear is pleased to provide this overview of the components that contribute to a safe rigging setup.

Rigging safety begins with a thorough understanding of industry safety standards, which are designed to protect everyone involved in the production, from the crew setting up the rigging to the audience enjoying the event. It’s crucial to stay updated on these standards and ensure that all equipment and practices meet or exceed them. Implementing robust safety protocols and regular inspections prevents accidents and ensures the well-being of all participants.

Training and Certifications

Rigging professionals should pursue comprehensive training and certifications to stay current with industry best practices. Certifications from organizations such as Occupational Safety and Health Administration (OSHA) are essential. Additionally, programs from the Event Safety Alliance (ESA) and the Entertainment Services and Technology Association (ESTA) offer valuable resources and training, providing latest knowledge and skills to perform their jobs safely.

Best Practices for Rigging Safety

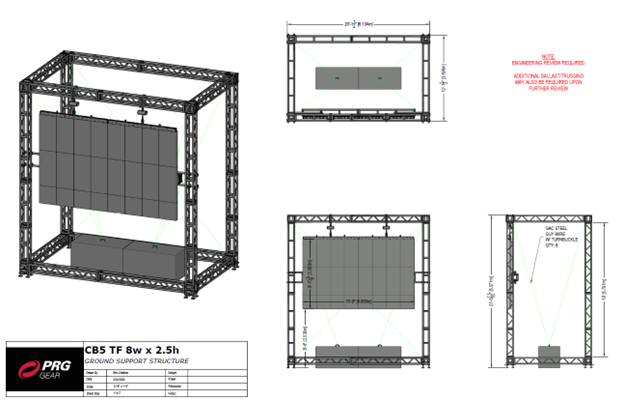

Plots and Drawings

Detailed drawings, whether on CAD or Vectorworks, are essential for planning and visualizing the rigging setup. They identify potential issues and ensure that the design adheres to safety standards. Drawings will lay out evacuation pathways and emergency procedures, adding an additional layer of safety. They also facilitate clear communication among the rigging team and other stakeholders.

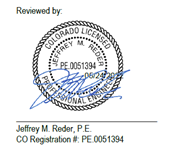

Wet Stamp Approval

Obtaining wet stamp approval from a reputable engineering firm, such as Clark Reder, is vital. Approval verifies that the rigging plot is safe, considering factors like weather conditions, load capacity and structural integrity. This isn’t always a necessary step: For example, you may not need it in a convention center where the rigging is already tested and approved. However, for most outdoor or custom setups, it certainly is.

Obtaining wet stamp approval from a reputable engineering firm, such as Clark Reder, is vital. Approval verifies that the rigging plot is safe, considering factors like weather conditions, load capacity and structural integrity. This isn’t always a necessary step: For example, you may not need it in a convention center where the rigging is already tested and approved. However, for most outdoor or custom setups, it certainly is.

Safety Equipment

When on-site, it’s crucial to have your rigging staff equipped with proper safety equipment, starting with a harness. Like a harness you would wear when rock climbing, a full body rigging harness allows riggers to be protected from a fall when working at heights. A harness has multiple positioning and safety anchors that can be used to link a rigger to a stationary object, such as a truss or fall-arrest system, preventing a fall in case a grip loosens.

Other accessories and safety gear to consider include lifeline solutions, climbing helmets, carabiners, positioning hardware, and lanyards. PRG Gear offers a range of protection and accessories specifically designed for rigging safety.

Equipment Maintenance, QC and Upgrades

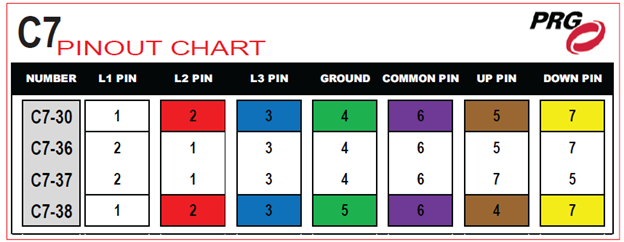

Regularly assess and upgrade your rigging equipment to maintain adherence to safety standards. A recent incident highlighted the importance of this change. We had a report of a hoist fly cable with a spinning barrel end connection. Upon powering up the system, electricity was inadvertently sent up the control side of the cable. This allowed power to travel through the hoist, ultimately arcing to the steel. Thankfully, no injuries were reported, but this incident underscored the need for an upgrade, and we promptly converted to the C7-38 pinout. This upgrade ensures a continuous ground connection even if the connector misaligns internally, thus providing enhanced protection for end users.

Quality control is essential for rigging gear. If you’re renting from a reputable provider like PRG Gear, you can be confident that each piece of rigging equipment undergoes rigorous QC both before and after each project.

Onsite Organization and Preparation

Effective onsite organization is key to a smooth rigging process. Techniques such as color-coding cases and products streamline deployment and reduce the risk of errors. Proper preparation ensures that the setup is both efficient and safe.

Community and Collaboration

Engaging with the rigging community can provide valuable support and insights. Online platforms, like Facebook groups for rigging professionals, offer a space to share experiences, ask questions and stay updated on industry trends.

Beyond online groups, consider attending rigging events to further expand your network. Attending a meetup such as the Event Safety Summit is a great way to meet like-minded people and expand your rigging knowledge.

Ready to Rig?

Safety is the cornerstone of any successful rigging project. By adhering to industry standards, upgrading equipment, maintaining thoughtful organization, and investing in training and community engagement, event professionals can ensure that their setups are secure and reliable.

PRG Gear provides all the services mentioned above. With a team of seasoned rigging experts, we can provide the drawings, obtain wet stamps for approval and even assist with on-site management and setup.

Explore our vast inventory of rigging gear and request a quote to get started. Not sure exactly what you need? Contact us to speak to one of our rigging experts.